The UK will experience extremes of weather, according to 2024 forecasts. Whilst the summers will be hotter and drier, colder and wetter conditions can be anticipated in the winter.

The impact of wind-driven rain on roof/wall intersections can be demanding and a critical consideration is how intersections are flashed and to what extent able to perform and maintain functionality with undulating pressure variances around the top of a building.

Driving rain accompanied with wind will breach a conventional running stepped flashing where pressure forces the water into the flashing leading edge. Once under the leading edge, water is immediately in contact with the back of the flashing and the (outer skin) fabric of the building - which becomes an internal wall below the roofline.

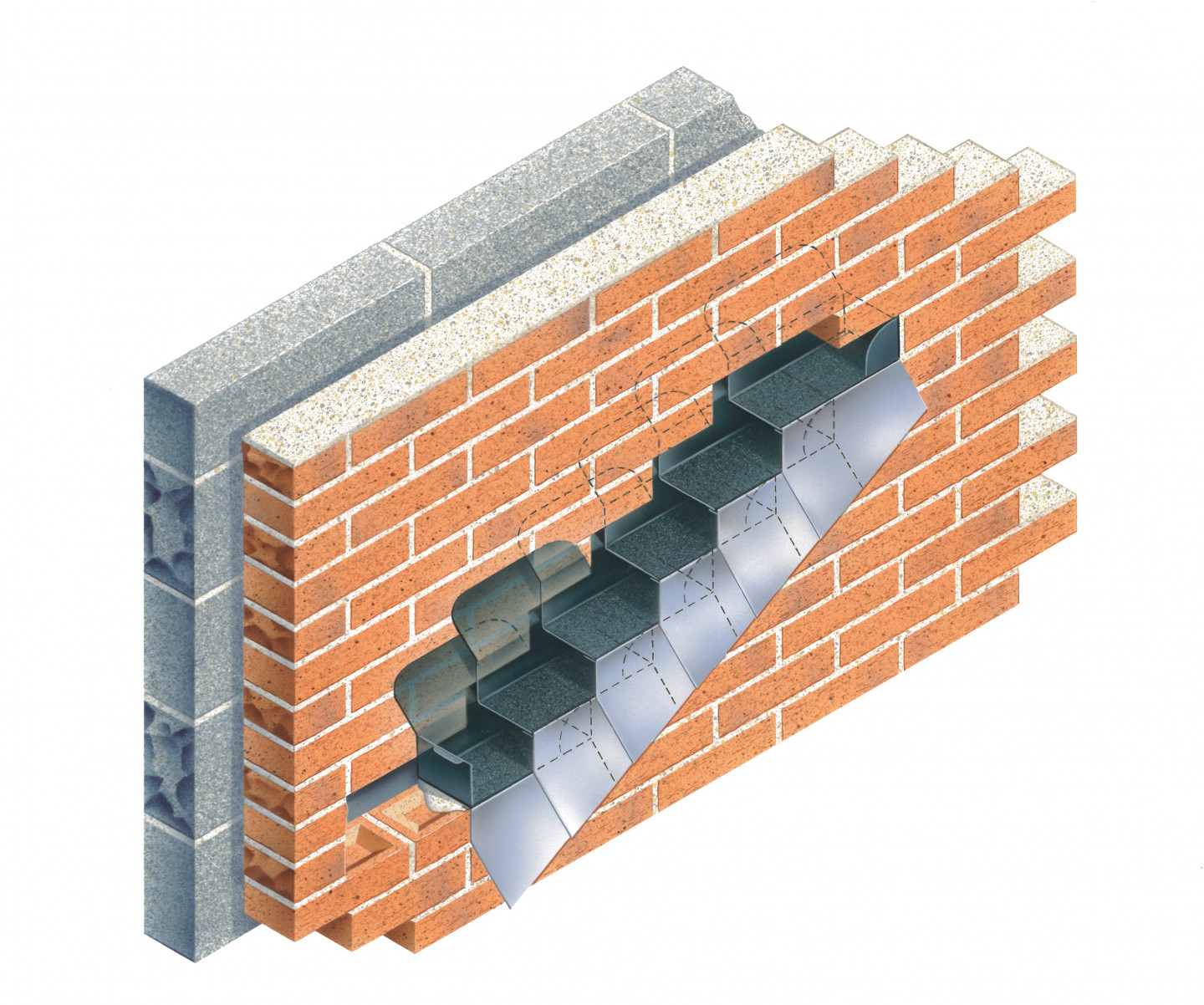

Running stepped flashings cannot provide the extent of protection enjoyed with the alternative: individual stepped lapping flashings. But most importantly, it is how such individual flashings are shaped, lapped, positioned and secured that dictates their capability.

Preformed Type X Cavitrays are manufactured specifically for stepped and staggered gable abutments and have individual stepped lapping flashings already attached. The flashings are shaped to suit the angle of the roof, and following building-in of the Cavitrays, require dressing only.

The relationship between individual tray flashings provides an overlapping arrangement wherein should water drive under the leading edge, it is arrested by the underlapping layer and safely discharged - away from the masonry area that remains protected. The flashing choices include lead, copper and synthetic options. All flashings are factory bonded onto the Cavitray via a bosem jaw, the most effective anchoring medium of all options tested by the Company. Cavity Trays Ltd has a history dating back to the 1920’s. It is the only cavity tray manufacturer awarded European Technical Approval and has recently celebrated 100 years of specialism.