The Institute for Advanced Manufacturing (IfAM) encompasses a multidisciplinary team of established academics with a foundation for research, in combination with world-leading facilities, to encourage the development of new technologies and systems for the production of high-value products within the manufacturing sector. The University of Nottingham completed its pioneering Advanced Manufacturing Building in the autumn of 2017, a state-of-the art 9,011 sqm training and research facility, situated on a former brownfield site that was designed by Bond Bryan Architects and built by GF Tomlinson.

The new building is an expansion of the University’s Faculty of Engineering, with a wide variety of teaching spaces, laboratories, modern workshops and offices for a multitude of research activities, including nano-scale production, robotics, automation, precision manufacturing, 3D printing, light weight composite materials and large-scale aerospace demonstrator components.

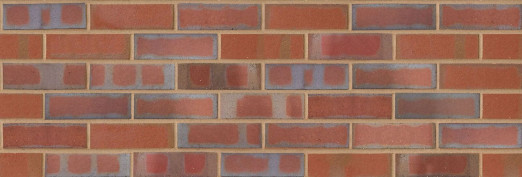

Located on Derby Road, the building provides a new south entrance to the University’s Jubilee Campus. When entering the building, visitors are greeted by the bold, homogeneous ground floor building plinth, which displays almost fifty thousand Blockley’s Smooth Black bricks, giving a sense of durability and strength. The masonry elements are seamlessly integrated alongside the glass, timber and steel elements showcased across the facades to form an articulate composition and coherent contemporary design that sits in harmony with its immediate built environment and surrounding context.

The IfAM is dedicated to supporting UK manufacturing to revitalise the British economy through innovation and collaboration, therefore it was fitting to construct the building using British made products such as those supplied by Michelmersh, Britain’s Brick Specialists. In combination with the brick manufacturer’s ethos, the University’s current research is concerned with developing new technologies and systems for cost efficient, knowledge intensive, high value and environmentally friendly production methods. IfAM addresses the full product lifecycle from development through to manufacture, usage and disposal.

Photography © Bond Bryan Architects

Photography © Bond Bryan Architects

Chris Jagger, chief estates and facilities officer at the University, said: “This pioneering project delivers a fantastic addition to the university’s portfolio of unique and ground-breaking buildings and it further enhances the continued growth of our Jubilee Campus. The project has also included a replacement new building for the 62nd Wollaton Park Scout Group, which will also provide facilities for the local community.”

Sajeeda Rose, senior manager for growth deals and capital programmes at D2N2, which has contributed £5m to the scheme, said: “The new institute will align with the Government’s desire for a new industrial strategy and the university’s project will help the area attract talented people and retain skilled graduates.”

Project architect, James Woodhouse said: “This project has been a fantastic team effort and a joy to see it come to fruition. We are all thrilled with the result and believe this will help to shape the future of the UK manufacturing sector.”