The Kingspan KoolDuct System has been installed as part of an ISO Class 8 Cleanroom for Zeus Juice UK, providing a lightweight and versatile solution for air distribution.

Monmouth Scientific Ltd is a market leader in the design and build of cleanrooms, including air conditioning. Its expertise has been used to create a bespoke facility in Birmingham for popular UK E-liquid manufacturer, Zeus Juice UK - its second site to open in three years. David Court, Operations Director from Monmouth Scientific, explained the specification of 220 m2 of the premium performance Kingspan KoolDuct System as part of the build:

“We chose Kingspan KoolDuct for the air-distribution ductwork, which we designed to the pressure value of 500 Pa as, in addition to its high performance, we are able to produce a wide variety of shapes and sizes using our computer numerical control (CNC) router. The product was fabricated in accordance with guidance from Kingspan, ensuring we could take full advantage of the product’s flexibility to fit specific applications or make onsite modifications easily with minimal waste.”

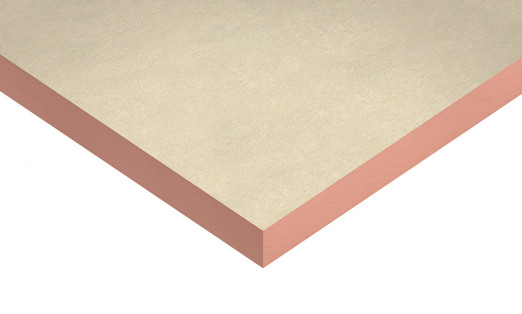

Kingspan KoolDuct is a pre-insulated rectangular ductwork system with a non-fibrous rigid insulation core, which is installed in a single-fix. Kingspan KoolDuct panels are lightweight and are available in up to 2.95 metre lengths and multiple duct sections can be joined together with a lightweight coupling system making the system easy to handle and fast to install.

David Court added:

“Complex shapes were constructed off-site, but most of the material was delivered to site flat packed and ready for assembly. This allowed us to save on significant transport costs.”

In addition, The System can reduce air-leakage rates to a fraction of lagged ductwork and can easily achieve: BS EN 1507: 2006 air–leakage Class D; BS EN 13403: 2003 Class C; and B&ES (HVCA) DW/144 Class C. This can help facilities to cut energy use and operational CO2, with up to 65% less embodied carbon than ductwork lagged with mineral fibre.

Kingspan KoolDuct panels are manufactured to the highest standards, having been certified to BS EN ISO 9001:2008 (Quality management systems. Requirements). The System has also been assigned a highest possible BRE Green Guide Summary Rating of A+ and is UL Listed as a Class 1 Air Duct, to Standard for Safety UL 181 (Underwriters Laboratories: Factory Made Air Ducts & Air Connectors), when fabricated to a specification clearly defined by UL.

For further information, please contact:

Tel: +44 (0) 1544 387 384

Fax: +44 (0) 1544 387 484

email: info@kingspaninsulation.co.uk

Website: www.kingspaninsulation.co.uk