Knock Basilica in County Mayo, Ireland, serves the Roman Catholic Archdiocese of Tuam and forms part of the Knock Shrine grounds incorporating four other churches. A large building with challenging design features, a solution was needed to ensure the refurbished building was sufficiently heated, especially during the colder winter months where the building was only frequented intermittently. M&E Consultants IN2 Engineering were hired in conjunction with A&D Wejchert Architects to design a heating system to control the indoor climate.

Objectives and Challenges

Knock Basilica can accommodate approximately 10,000 people, and is attended both by local parishioners and also a vast number of pilgrims and tourists who travel to the shrine grounds each year. Originally built in 1976, the Basilica features extremely high ceilings and a huge inside space, presenting a challenge in terms of heating the building. Particularly during the winter, cold discomfort issues were often experienced within the chapel areas by the parishioners and visitors

Key Considerations

- Ceiling heights: A solution was needed to heat the entire space, accommodating ceiling heights of up to 30m.

- Design features: The design brief showed a number of curved false ceilings which presented its own challenges and complexities.

- Cost efficiency: It was deemed uneconomical to reconfigure the existing air handling units, as the ceilings were so high and as warm air rises, this would result in high lifecycle and maintenance costs.

- Comfort: The existing system meant that air was being distributed ineffectively, making the temperature uncomfortable for occupants.

- Response time: The Basilica often lay vacant for months and was only used intermittently, so an engineering solution was required which was responsive only when needed.

The Solution

- The Solution

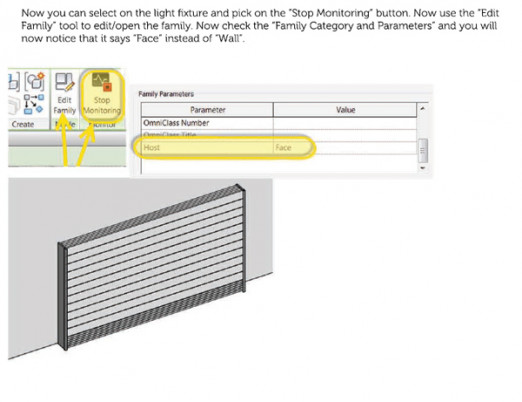

Tasked with finding a cost and energy efficient heating solution that could overcome these challenges, M&E consultants IN2 Engineering approached Versatile, Zehnder’s Irish distribution arm, to implement a Low Pressure Hot Water (LPHW) radiant solution, to be integrated in the ceiling to heat the space.

LPHW Radiant panels were the preferred choice for this project as radiant panels do not heat the air, they heat the surfaces or objects they reflect on and in turn, those objects or surfaces act as radiant panels.

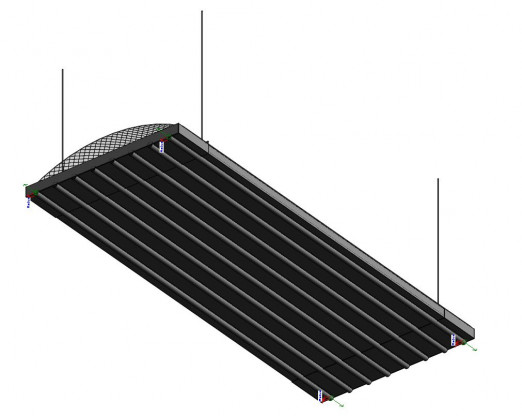

Zehnder and Versatile provided a solution which complemented the Basilica’s unique design, integrating radiant panels into the curved ceiling sails, contributing to the absorption of noise as well as heating the congregation space effectively and rapidly.

Key Priorities

- Radiant panels are considered to be a viable alternative to conditioning air through traditional ducted systems and fan coil units.

- The use of radiant panels means no moving parts, no filtration and no draughts, drastically reducing running costs and the negative impact on indoor air quality.

- A radiant heating and cooling system will work in conjunction with the fabric mass of the building in direct heat transfer and storage, helping to achieve the required comfort level at a reduced energy input and cost

- If required, some panels on the market can incorporate lighting, sensors, and other services, all of which reduce installation time, cost and risk.

“This project required a very specific solution that would meet the unique needs of the Basilica, with its large dimensions and varying levels of occupancy. The panels provided by Zehnder and Versatile delivered the required levels of efficiency and flexibility, meaning that the building could be heated to a level that was comfortable for all visitors while saving on energy and cost.” said David Walshe, Technical Director at IN2 Engineering.