Focus on core application areas, close customer contact, and collaboration is bearing fruit

The technical weavers for industry and architecture GKD - Gebr. Kufferath AG (GKD) achieved their second-highest revenue in over 90 years since the company's foundation, with group revenue of 87.0 million euros (previous year: 83.0), and all sectors and regions successfully contributed to this strong performance. This enabled the company, now in its third generation of private ownership, to further expand its position as global market leader in defined niche markets in all business areas. For the fifth time in succession, GKD also increased investments in further growth in the reporting year: 5.25 million euros (previous year: 5.1). In addition, the equity ratio of 56.5 percent (previous year: 54.9), which increased once more, reinforces the need to invest in future markets and technologies in order to shape rapid growth. As at December 31, 2017 GKD employed 764 people across the Group (previous year: 699), 443 of them (previous year: 423) in the company headquarters in Düren. The stable number of 22 interns highlights the sustainability of the Group's HR policy.

Within the project Optimized Materials and Procedures for Removing Microplastics from the Water Cycle (OEMP), GKD developed the optimized dutch weaves ODW6 and ODW8, which are unrivaled in their fineness. © GKD

Within the project Optimized Materials and Procedures for Removing Microplastics from the Water Cycle (OEMP), GKD developed the optimized dutch weaves ODW6 and ODW8, which are unrivaled in their fineness. © GKD

GKD Director Dr. Stephan Kufferath summed up the company's development, saying of the past year,"Despite a challenging and volatile market environment, we are very satisfied with how the financial year has developed. All business areas - filtration technology, process belts, architecture, and the mining industry - have grown consistently." His brother and fellow Director Ingo Kufferath adds,"The growth in revenue was driven by focusing on the core application areas we have defined and consistently expanding our global multi-platform strategy." The technical weavers specifically serve growth areas that respond to global needs such as water, food, health, mobility, and protection of the environment and resources. The range of branches in which GKD is active as a leading global niche player is accordingly broad: the automobile, chemical, electronics, timber, foodstuff, paper, pharmaceutical, and textile industries drew on the company's woven high-tech solutions in the last financial year just as much as mining, aerospace, medical and environmental technology, architecture, and design. Based on the cross-sector problem-solving competence, leadership in technology, and innovative power that have been built up over decades, GKD develops and produces products that contribute to making the world safer, cleaner, and healthier.

Leading technologies as drivers in all sectors

The strongest driver of growth in the field of filtration technology was the worldwide automotive industry, for which GKD produces a wide range of customized components for various units. There was also increased demand for innovative filter media from the family-run business in municipal and industrial water processing. Following intensive research activities in the previous years, new products generated relevant revenue here for the first time in 2017. From 2018 onward, GKD expects to see a significant revenue contribution from this application area. In the process belt sector, the usage areas of sewage sludge dewatering and nonwovens production delivered strong revenue contributions. At the same time, this business area put a production line for spiral belts into operation in this reporting year, which generated revenue from day one. Just one year later, a fully automated machine is already planned here to reinforce GKD's leadership role with this new product line. Stephan Kufferath says of this,"through innovative material combinations and constructions for the spiral belts we want to break into new business areas and markets in order to become the preferred technology partner in this area, too." The architecture sector upheld the same aspiration in the 2017 financial year to impressive effect. It was the first, and as yet only, provider on the market to receive general building approval (abZ) for façades, suspended ceilings, and vertical fall guard protection made from stainless steel mesh from the German Institute for Structural Engineering (DIBt). For planners, installers, and builders this constitutes a significant advantage in the approval process, as it renders time-consuming and costly approval on a case-by-case basis (ZiE) redundant. The strongest revenue generator in the architecture sector in the reporting year were the acoustic ceiling systems which were developed in-house as a result of heavy investments in the preceding years. The sector also roused worldwide media interest with two major projects: in addition to the Kunsthalle Mannheim, the new company headquarters of the Chinese Internet giant Tencent provided impressive proof of innovative mesh designs. With the market launch of roll-up doors and roll-up solar protection systems made from high-grade mesh with proven technology from well-known system partners, GKD also laid the foundation in 2017 for new growth in the field of architecture.

Wherever seamless belts are an indispensable component in dewatering, transport or drying processes, spiral fabric belts from GKD help to secure the required level of production efficiency. © GKD

Wherever seamless belts are an indispensable component in dewatering, transport or drying processes, spiral fabric belts from GKD help to secure the required level of production efficiency. © GKD

Global division of labor for tailored close customer contact

Across the Group, GKD achieved particularly strong revenue growth in Asia and Australia. At GKD India, the fine mesh platform that had been heavily expanded in 2016 and 2017 started to have an effect. It is used by the site not only to serve the Indian market but is also one of the supporting pillars of the Group-wide global division of labour initiated in 2016. Thanks to this multi-platform strategy, GKD possesses a highly complex value added chain. GKD China developed very well at the new site in Qufu. Filtration applications in the water and sewage segments are a promising area here for 2018, too. The sales location GKD Australasia, which is still small, succeeded in significantly improving its revenue in the last business year. This result comes primarily from products for architecture and mining. GKD Middle East met the expectations set for the site for a positive turnaround. Striking proof of this achievement takes the form of a transparent media façade in the Ministry of Education in Kuwait. The second-largest revenue generator in the GKD Group by far was GKD USA. This location recorded strong growth both in architecture and in the industrial sector. Due to the rise in the oil price, oil business also gained momentum there at the end of the reporting year. The development of GKD LatAm was exceedingly positive. With two major projects in the architecture sector in Panama and Columbia, this site in South America is able to look back on very successful sales development in 2017. However, development was not so successful at GKD South Africa. This was attributable to mining strikes in the platinum industry and meant that an upward trend wasn't recorded until the end of the year. Nevertheless, the new polyurethane flooring product lines that GKD South Africa produces for the local market developed well. In Europe GKD recorded good sales growth in the architecture sector in particular. Alongside the head office in Germany, it was France that made the biggest contribution to the positive result. As Brexit is causing a considerable reduction in the market potential GKD is able to realize in Great Britain, the company decided to close the production site there in the last business year and to serve this market, like all others in Europe with the exception of Germany, with a local sales unit as of 2018. GKD Director Stephan Kufferath sees the situation in the USA as completely different,"We are convinced that it is important for the GKD Group and the applications served to continue to increase our presence in the USA and to make strong investments there - regardless of the current political situation."

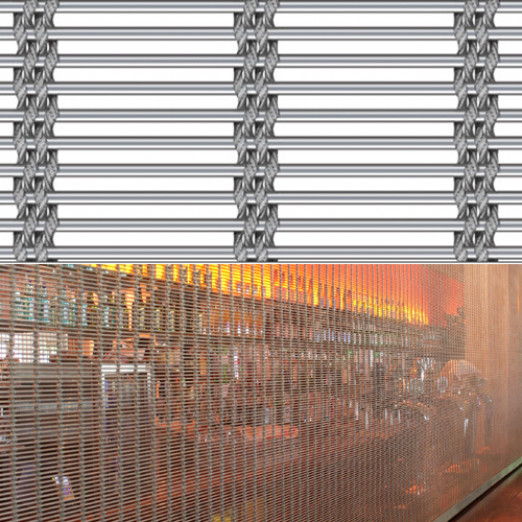

The certified mesh façades made of the TIGRIS and OMEGA 1520 cable meshes as well as the ESCALE 7x1 spiral mesh made of stainless steel from GKD, including the matching end and intermediate fixings, are classified as regulated construction materials. © GKD

The certified mesh façades made of the TIGRIS and OMEGA 1520 cable meshes as well as the ESCALE 7x1 spiral mesh made of stainless steel from GKD, including the matching end and intermediate fixings, are classified as regulated construction materials. © GKD

With investments totaling 5.2 million euros in machines, plant, and digitalization, GKD energetically drove the company's continued focus on the future in the 2017 financial year. "We don't just want to keep pace with the dramatic changes taking place in the world, we want to secure our advantage and build on it," says Ingo Kufferath. That's why GKD is consistently banking on modernizing, automating, and expanding the capacity of production. Alongside another loom for hybrid weaves, last year this included the expansion of automation, another cleanroom for the production of exhaust gas recirculation filters (EGR) for the automotive industry, new plants for manufacturing automotive products, and the setup of a complete production line for spiral belt production. In addition, GKD has been working intensely on the digital transformation of all business processes for several years."In view of the enormous increase in the complexity of processes, structures, customer requirements, and quality requirements, we need to have a firm handle on our production and value-added processes so that all information is available, valuable, and in the process at all times," states Ingo Kufferath. It's a view that his brother shares,"there's no avoiding Big Data: more than any other factor, it is digitalization that dictates the future viability of products, processes, and companies." That's why GKD once more invested in expanding its software infrastructure in the past year. Plus, the company headquarters in Düren became the second location in the Group after GKD India to be certified in accordance with ISO 9001:2015. Certification of the remaining Group locations will be completed in the current financial year.

The certified mesh façades made of the TIGRIS and OMEGA 1520 cable meshes as well as the ESCALE 7x1 spiral mesh made of stainless steel from GKD, including the matching end and intermediate fixings, are classified as regulated construction materials. © GKD

The certified mesh façades made of the TIGRIS and OMEGA 1520 cable meshes as well as the ESCALE 7x1 spiral mesh made of stainless steel from GKD, including the matching end and intermediate fixings, are classified as regulated construction materials. © GKD

All indicators point to growth

All indicators point to growth For 2018 GKD expects continued significant and consistent growth in all sectors in the most important of the defined target markets. Stephan Kufferath is particularly optimistic about the locations in the USA and India stating,"We have achieved great progress in many projects and strategic initiatives that will continue to bear fruit." GKD is responding to the expected bettering of the second-highest revenue in the company's history achieved last year with even greater investments: in addition to further capacity expansions with machines and plant, there are also plans to expand the head office in Düren in 2018. It meets the increased demands on research and development as well as on IT to optimally focus all processes in the interest of creating benefit for customers. In this way, the family business is continuing with the strategy of sustainability in solutions, customer relations, and processes that it has pursued for almost ten decades. Ingo Kufferath adds:"On the basis of our cross-sector and cross-border collaboration, we are continuously developing new ideas, business areas, and markets. Our secret weapons forever more flexible solutions to new customer requirements are our close customer contact and speed of response."