Industrial floor covering specifications are extremely challenging: They have to ensure safety for highly developed technical appliances, be highly resistant to wear and chemicals, have ideal cleaning properties, be ergonomical for employees, and much more besides. What are required in this demanding market are therefore high performance products such as rubber floor coverings from nora systems. They are installed in many industrial buildings worldwide: production and assembly workshops, cleanrooms, ESD areas, laboratories and research facilities, as well as in offices and administrative buildings.

Floor coverings from nora are "Made in Germany" and are manufactured from premium quality industrial and natural rubber. The outstanding quality of the finished products makes them highly resistant to abrasion and wear. They still look almost like new even after decades of use in heavily frequented areas. This unusually long service life contributes significantly to their economic viability and the long-term value preservation of buildings.

Made-to-measure solutions for every building

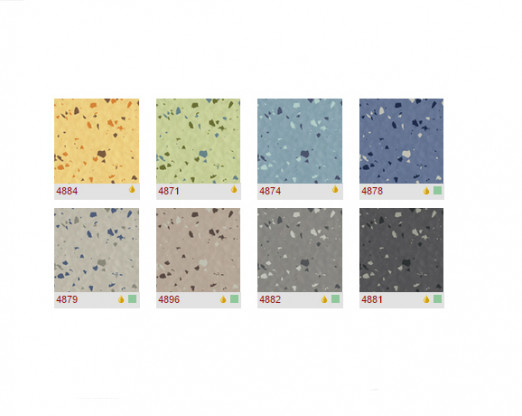

The advantages of rubber are exploited to the full in industrial buildings with their multifarious demands regarding design and functionality. Flooring coverings from nora allow the realisation of integral design concepts that incorporate varying functional characteristics. Architects and designers can choose combinations from the standard range comprising over 300 variations of colours, designs and surfaces. This means that individual specifications can be fulfilled at all times: More than two thirds of placed orders are custom-manufactured at nora systems. Regardless of whether a special colour is required, or the surface texture of a rubber floor covering needs to be combined with the technical characteristics of another covering - the nora team is expert at implementing made-to-measure solutions.

Designers at the agency Bright 3D envisaged a flooring in expressive, accentuating colours to emphasise the innovative room concept when they were designing the offices of Europe's largest flight search engine, Skyscanner, in Edinburgh, Scotland. Another key aspect for the planners were good room acoustics, since around 300 people work in the open plan office. Bright 3D opted for the rubber floor covering norament 975 LL in the serra design with a relief surface, but preferred the colours of the norament 926 crossline covering, which had been exclusively designed for nora systems by designer Lars Contzen. No problem for nora. The Skyscanner office now revels in norament serra in the special colours pink, green and turquoise, providing for trendy surroundings and ultimate comfort.

ESD protection for sensitive manufacturing areas

Floor coverings from nora score points even where special technical properties such as electrostatic discharge capabilities are required. Keinath Electronic GmbH, for example, a leading technology consultant in the fields of ESD protection and soldering systems for companies in the electronics industry, has been recommending nora systems products for years. "Due to their material properties, rubber floor coverings possess generate minimal potential from people and dissipate static electricity, protecting sensitive electronic appliances," explains Stefan Proba, technical manager and accredited ESD consultant at Keinath. When renovating its own headquarters, Keinath again resorted to nora floor coverings and chose norament 928 grano ed, an extremely popular product in the electronics industry.

Safety for cleanrooms

The Weinheim-based rubber specialists also offer the ideal solution for research and production cleanrooms in the pharmaceutical, medical equipment, food and animal feed industries. The specifications that have to be met by floor coverings in these sectors are extremely stringent: low particle emissions, a non-porous and non-slip surface, resistance to static and dynamic loads, and extremely good cleaning and disinfecting characteristics. Selected nora floor coverings have been tested by the Fraunhofer Institute for Manufacturing Engineering and Automation and certified as being compliant up to ISO Class 2 and GMP Class A. They are also highly resistant to biological contamination, chemicals and disinfectants.

Easy and economic cleaning

Regardless of which area of industry: With their durable, and abrasion-resistant surface, nora rubber floor coverings can be perfectly cleaned since their extremely dense surface obviates the need for a coating. This has several advantages. In contrast to coated surfaces, for instance, nora floor coverings are immune to unsightly signs of heavy traffic. But what is even more important is that the coatings of other resilient floor coverings have to be replaced at frequent intervals because they wear out quickly. This is not only expensive, but also leads to considerable operational disruptions during refurbishment.

On account of its durability and ease of cleaning, the unique rubber surface has proven itself even in heavy traffic production areas, on stairways and in corridors. This is also confirmed by Thomas Volk, project manager at the Facility Management division of Bosch in Abstatt: "The flooring we installed in 2004 is still to be found almost unchanged today in the technical rooms. In 2009 it was therefore an obvious decision for us to have rubber floor coverings from nora laid in the new extension to the development centre." In total, 16,000 square metres of flooring have been installed in different areas. This area, equivalent to about two football pitches, copes with the toughest demands day in, day out.