The model is of the world’s first bioplastic 3D printed house, located by a canal in Amsterdam North. The house is printed with the KamerMaker – a large FDM printer that can print elements of 2 x 2 x 3.5 meters. This project has been developed by DUS Architects collaborating with international teams of experts from various sectors, with the aim of offering tailor-made housing solutions globally. The canal house has 13 rooms, each showcasing a research update in shape, structure and material.

Loop

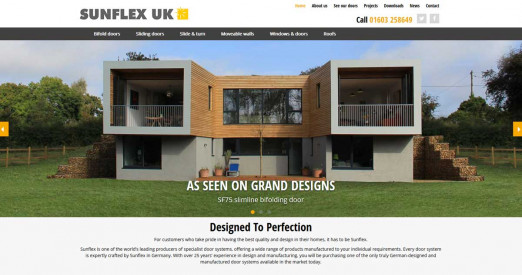

Façade Fragment, Model. DUS Architects (3D printed bioplastic Amsterdam, Netherlands, 2016)

DUS architects was founded by Hans Vermeulen, Martine de Wit and Hedwig Heinsman in 2004.

What does DUS stand for?

DUS architects: DUS means ‘SO’ in Dutch and to the founders of the company stands for ‘Design by Doing’ thus: Acting and Making.

DUS describes itself as doing ‘public architecture’. What do you envision as the ‘public’ and what is the architect’s role as part of the ‘public’?

DUS architects: Architects have a public responsibility as they give shape to the public domain. Our focus is not primarily on our clients but ultimately with the people that will interact with our buildings.

Your ‘Momentary Manifesto for Public Architecture’ expands the notion of architecture – from ‘making cookies’ to ‘playing’ the city rather than ‘planning’ it. Where does the 3-D printed Urban Cabin sit in the manifesto?

DUS architects: The Urban Cabin is part of the ‘3D Print Living Lab’ in which an international team of experts from different sectors works on the development of digital production tools for the building industry, to develop novel housing solutions that can be implemented worldwide. This directly relates to our belief that architects have public responsibility and our quest to make architecture accessible to the masses.

What inspired this project and could you tell us a little about the process – from organising the printer and the site to how you responded to the instant feedback from visitors?

DUS architects: The 3D Print Living Lab and the ongoing research and development on the 3D Print Canal House (The larger brother of the Urban Cabin) stems from our fascination to democratise architecture via the help of digital networks and digital manufacturing techniques. This inspired us to develop the KamerMaker (Roombuilder), a portable XL 3D printer. Development and building of the XL Printer happened outside, in the public domain, which over time generated a mega interest from the public. This created a snowball effect that led to a growing eco system of over 20 international partners with the plan to 3D Print a Canal House and start a 3D print Living Lab for the building industry.

More info on DUS Architects