Join Aggregate Industries at the Building Centre for an October CPD on the effective use of thermal mass in sustainable construction. The sessions will be supported with breakfast refreshments in the Vincent Suites. Refreshments will be served at 08:30. The session will begin at 09:00 and finish at 10:30

The thermal mass of concrete (Aggregate Industries – Eirini Mantesi)

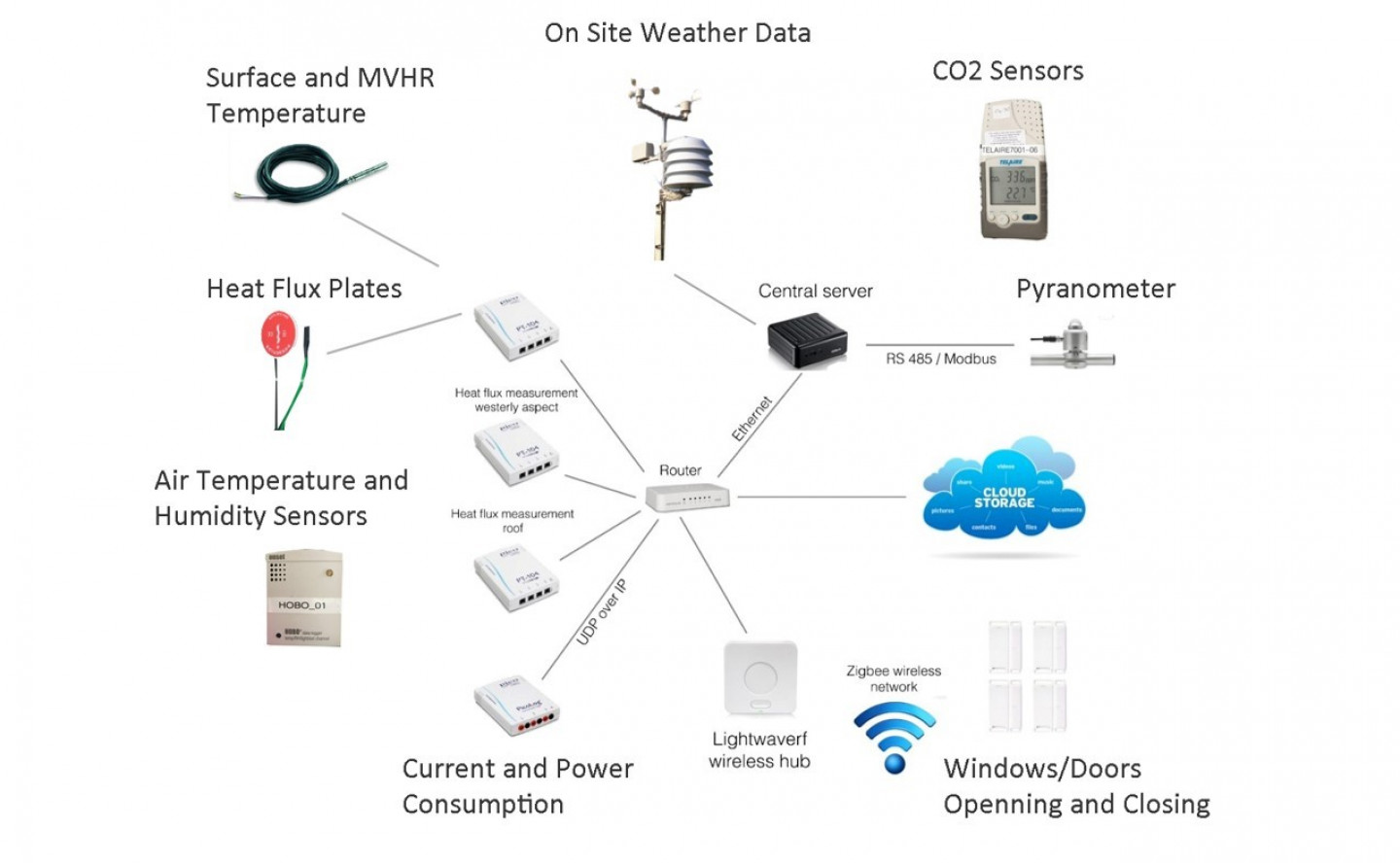

The thermal storage capacity of high thermal mass buildings is a well-known passive technique used to moderate the internal temperature swings in a building. It can also serve as a means of the building’s adaptation to climate change and prevent it from overheating. There are several factors that affect the effective use of thermal mass in low-energy building design. Apart from the materials’ thermal properties, there are other parameters that need to be taken into consideration, such as the location and distribution of the mass in the building fabric, its positioning in respect to insulation, the ventilation and occupancy patterns within the building and others. Ms Eirini Mantesi is a final-year doctorate of engineering (EngD) student at Loughborough University, in the School of Architecture, Building and Civil Engineering. Her project is sponsored by the EPSRC and Aggregate Industries and focusses on the computational and empirical evaluation of high thermal mass buildings’ performance. In the session she will analyse the main design considerations associated with the effective deployment of thermal mass in respect to buildings’ energy efficiency. She will also present some preliminary results from computational and monitoring studies conducted in high thermal mass buildings, as part of her doctorate project.

Benefits of Lightweight Aggregate

Barry Mellor - Lytag

Lytag® is a lightweight aggregate which is up to 50% lighter than natural aggregate. Made from the fly ash generated by coal fired power stations, our proprietary technology transforms the fly ash into small round hard pellets, which are then heated to 1,100°C.

Using lightweight aggregate can reduce the weight of concrete in a construction project by over 30% without any loss in strength and significantly reduces the overall volumes of concrete and reinforcement. Lytag can also be used to form a lightweight screed, comprised of a lightweight aggregate traditionally bound with cement.

The various uses of lightweight aggregate in construction will be discussed in this session.

To secure your place please book with Abbigayle Morris abbigayle.morris@aggregate.com