v>

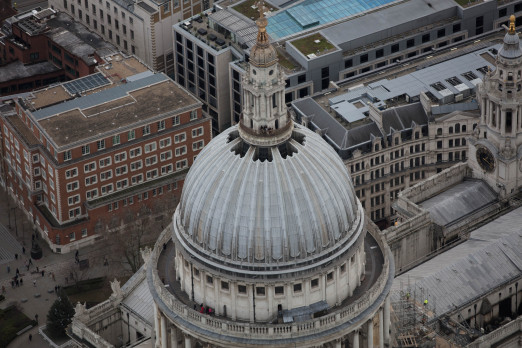

Tower Bridge is an instantly recognisable symbol of London, a world famous example of Victorian engineering skill. It’s a major tourist attraction but it’s also a busy working bridge, crossed by 40,000 people (vehicles, pedestrians and cyclists), and opened for river traffic at least a couple of times every day. So closing this iconic bridge in September 2016 for three months, to allow contractors to replace decking and resurface walkways, made for a very high-profile project. Bam Nuttall, the main contractor working for The City of London, employed O’Rourke Contracting plc to reconstruct the carriageway and walkways. O’Rourke sub-contracted the mastic asphalt work to Infallible Systems working with IKO PLC.

The challenge for Infallible was to strip back the existing mastic asphalt and replace it on the pedestrian areas around the base of the bridge’s main towers and walkways, while at the same time minimising disruption to the daily pedestrian and river traffic. Weight restrictions prevented the contractor from using heavy lorries or machinery on the bridge, so the material could not be delivered directly to where it was used. It was also necessary to complete the project as quickly as possible to reopen the road to vehicles.

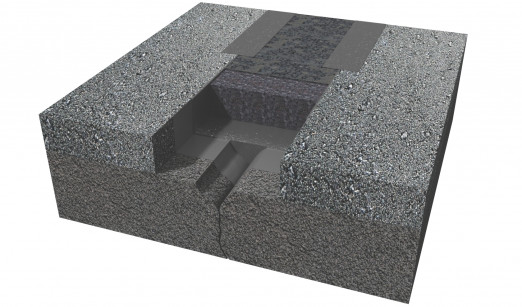

The old mastic asphalt had performed well so it was decided to use a similar material for the refurbishment. Mastic asphalt provides a hard, durable and long-lasting material, and with no joints or trip hazards, it was ideal for a pedestrian walkway in such a busy location. Infallible proposed a polymer-modified mastic asphalt which is used extensively as the surface course for expansion joints on both raised structures and a wide variety of bridge decks. No compaction was required, saving time and resource.

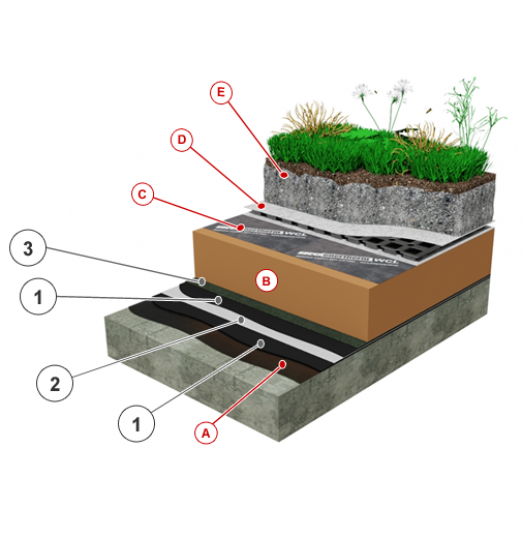

Mastic asphalt also offers high stability and no impact sensitivity, accommodating structural movements without fracturing or cracking. A surfacing system was used for the pedestrian areas around the base of the main towers, as waterproofing was necessary to protect the bridge operating machinery which is situated below the walkway.

Chris Hayward, Chairman of the City of London Corporation Planning and Transport Committee comments: ‘The decision to close Tower Bridge to vehicles was not taken lightly, but I am immensely pleased at how well the project went. We were particularly happy to open the Bridge a week early as a Christmas present to all Londoners. I would like to thank local residents, businesses, and of course commuters for their patience while we undertook this essential work. Tower Bridge will continue as a defining landmark for London, as well as a vital river crossing of the Thames for decades to come.’

John Chapman, Director of Infallible Systems, on the challenges of the project: ‘We knew the schedule was tight, but achievable if the weather was reasonable. Having hot charge deliveries from the manufacturer – approximately 400 tonnes of material ‘ready to lay’ as and when we needed it – helped us keep to the tight schedules and minimise disruption. However when we started work on the main piers, we found the asphalt we had to remove was 160mm thick, much more than expected. We replaced it with a 10mm waterproofing layer and a bridge surfacing layer to an average depth of 30mm. We broke out 400 tonnes of material, cleared it and replaced it with new, handling 800 tonnes altogether – all without having any lorries or machinery on the bridge due to weight restrictions!’

Wayne Perrin, Business Development Manager for IKO PLC, which supplied the mastic asphalt, comments on the carbon impact of the project: ‘Carbon emissions from 400 tonnes of mastic asphalt product were offset through a selection of projects, most notably CO2balance’s Kenyan Energy Efficient Stove Project.’

IKO PLC and Infallible Systems were shortlisted for the Tower Bridge project in the Mastic Asphalt/Hot Melt category in the NFRC UK Roofing Awards 2017.

.jpg)