As the manufacturers of both Qwood and Dacatie Insulated Cavity Closers we are well placed to understand the importance of quality within the timber window industry. This understanding links how a well finished window should be fitted correctly into the variety of reveals found in buildings in the UK.

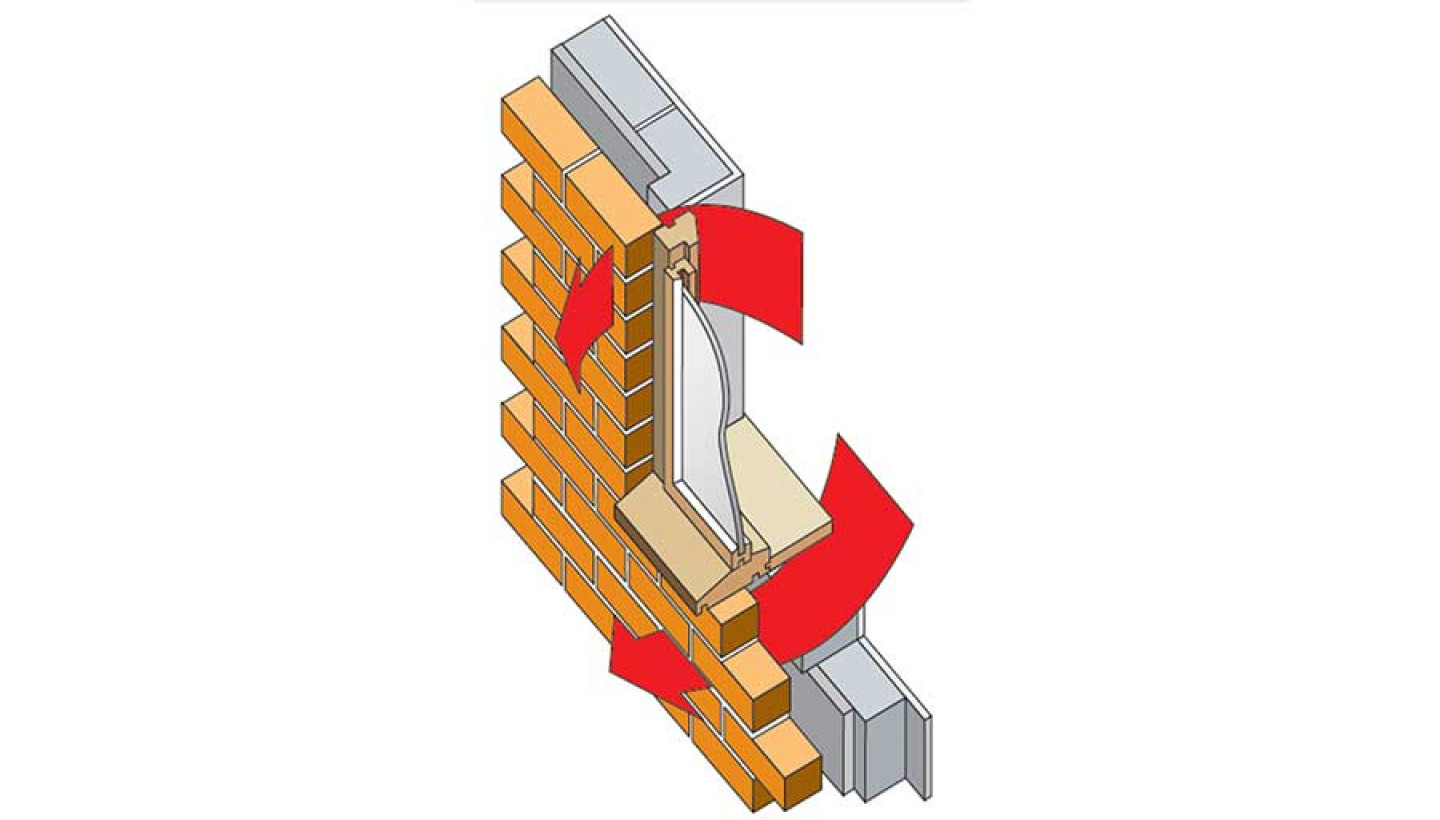

Why are Insulated Cavity Closers important for you to consider? Well if a cavity is not correctly closed around a reveal water ingress can occur, which will cause the seeping of damp and mould around the frame. As the person in the property can’t see any cavity closers they blame the window. This happens even though the window has been fantastically and lovingly constructed! This is why one of the main reasons why it is important to take in to consideration what cavity closer are used when your finished windows are installed.

There are a number of reasons for having a good Insulated Cavity Closers:

- Prevent water penetration – The use of a cavity closer will prevent the ingress of water around a window or door, as required for compliance with Building Regulations Part C. To achieve this it is important to set back the frame of a window a minimum of 30mm in to the cavity and to seal with a recognised sealant around the frame. Also a cavity closer with ridges on will further help prevent water penetration.

- Prevent heat loss and cold penetration – Cold bridging is when an area of a building has significantly higher heat transfer than the surrounding materials resulting in an overall reduction in thermal insulation of the building. The problems of cold bridging are recognised in the Building Regulation Part L. Insulated Cavity Closers are used to overcome thermal loss that occurs around unprotected cavities and reveals. Thermal loss can result in problems of condensation, staining and mould growth at the reveals of these openings. Prolonged exposure to such factors will lead to a deterioration of the internal plaster and paint work. The use of cavity closers will help to prevent the occurrence of such factors.

- Create a fire barrier – To comply with Building Regulation Part B a fire rated cavity closer should be used. A fire rated cavity closer can prevent the spread of fire for up to 1 hour. A purely insulted cavity closer without a fire rating will not actually comply with part B.

- Comply with Part L – Building Regulation Part L compliance is ever more important with sustainability being continually pushed up the agenda, therefore the more you can reduce heat loss the better. The minimum thermal resistance path through the cavity closer must be at least 0.45m2k/W the higher this number the lower the heat loss.

How to select a cavity closer – what questions to consider:

- Has the building been built? If it hasn’t you want to fit a 1st fit product, if the windows are just being replaced you want to select a 2nd fix cavity closer.

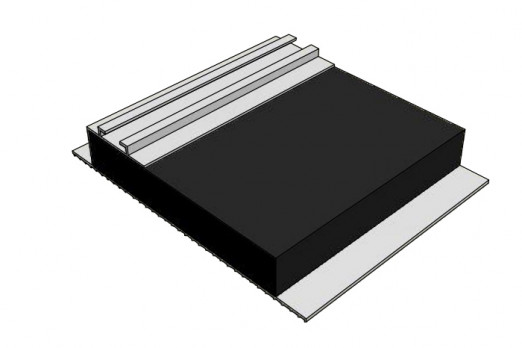

- How large is the cavity? Simple, if the cavity width (the distance between the brick and block) is 70mm then you require a 70mm wide cavity closer.

- Do you want to comply with Building Regulations C, B and L? If you do then select an insulated fire rated cavity closer with a minimum thermal resistance path of 0.45m2k/W, this value is also known as the R Value. All cavity closer manufacturers will be able to provide you with this information.

If you want to learn more about cavity closers, we have a RIBA approved video CPD, which can be watched at your leisure to explain how to pick or make sure the correct cavity closer is being used.