Leading interior linings manufacturer, British Gypsum, has been selected to provide products for an innovative new insulation system that improves energy efficiency in homes.

Matilda’s Blanket, a high performance Internal Wall Insulation (IWI) system designed by energy conservation specialists, Matilda’s Planet, uses a range of British Gypsum products to ensure durability, quality and ease of installation.

Created for solid wall properties, Matilda’s Blanket is well placed to meet the needs of the growing off-site manufacturing sector. The panels used to create the system are custom built for each project, enabling them to be fitted with ease, minimising disruption to residents and all but eliminating waste during installation.

Sean Mclaughlin, managing director of Matilda’s Planet, explained: “The UK’s existing housing stock is among the oldest and least energy efficient in Europe – a challenge that Matilda’s Planet is committed to addressing through our IWI system.

“To achieve our goal, we needed a partner that could not only provide high-spec thermal products, but also give us guidance and support in creating a truly innovative product suitable for use in the widest possible range of project scenarios.”

British Gypsum’s Rigidur H gypsum fibre board was specified for the front face board of Matilda’s Blanket, as its highly durable finish does not require any plastering or wet trades. The product also helps ensure a quick installation process that is of minimal disruption to tenants/householders.

For the IWI system’s back board, Glasroc F Multiboard, a non-combustible glass reinforced gypsum board, was selected to provide high levels of fire and impact protection.

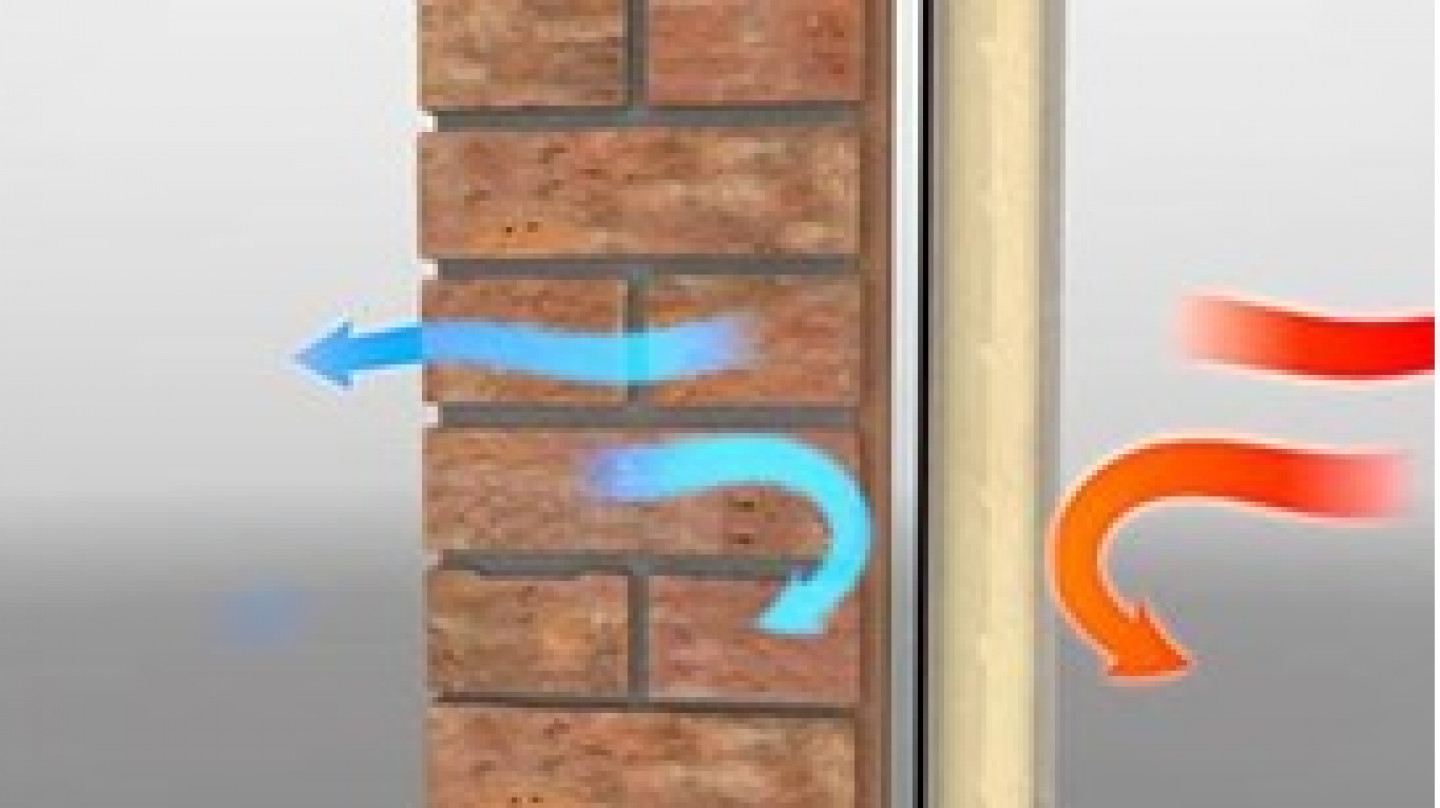

To ensure the system also provided high levels of insulation, Gyproc ThermaLine PIR was chosen. Featuring 12.5mm Gyproc wallboard bonded to highly insulating rigid polyisocyanurate (PIR) foam, Gyproc ThermaLine PIR is estimated to save over 1,000 times more energy than is needed to produce it over a 50-year period. It also offers a high-performance vapour control barrier to help manage moisture levels in external walls and minimise the risk of damp inside the property.

Sean concluded: “Thanks to the expert guidance and specification of products from British Gypsum, we’ve been able to develop a system that not only reduces home energy consumption by an average of 40 per cent, but also supports newer ways of working, such as off-site manufacturing.

“All of this will help us continue to improve energy efficiency in homes for the future, while also cutting the carbon footprint of the built environment.”

To find out more about how British Gypsum products can support off-site manufacturing, visit http://www.british-gypsum.com/offsite.